Global metal stamping market

The global metal stamping market is projected to be worth US$ 250 billion by 2027 at a CAGR of 3.5%, according to a new report on ResearchAndMarkets.com. It had already reached a value of US$ 198.3 billion in 2021, it confirmed.

“Keeping in mind the uncertainties of COVID-19, we are continuously tracking and evaluating the direct, as well as the indirect, influence of the pandemic on different end-use industries. These insights are included in the report as a major market contributor,” said the analyst.

“Metal stamping dies are relatively less expensive to maintain and produce than those used in other processes. The secondary costs, including plating and cleaning, are also cheaper than similar treatments for other metal fabrication processes. Besides this, the high level of automation and the employment of high-end computer-control programs in stamping machines represent major metal stamping market trends,” it added.

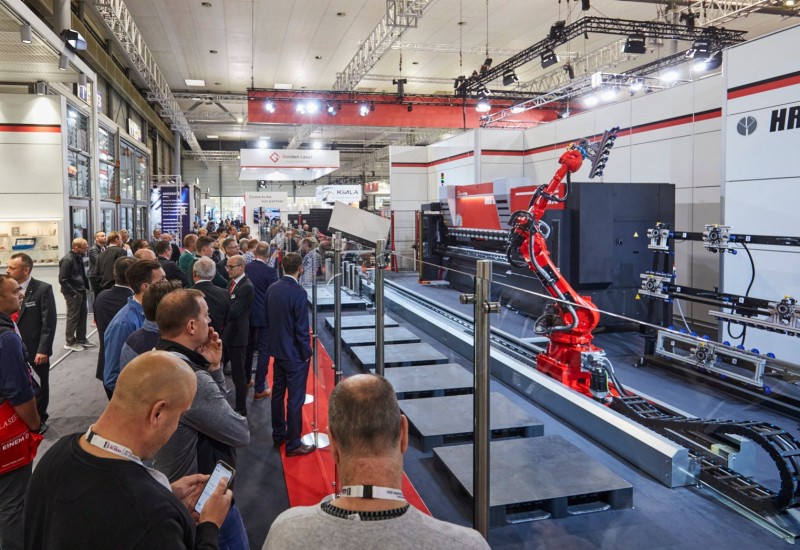

Nowadays, in most manufacturing plants, the entire blanking process is automated and monitored through computers. The data is available with the central server, which helps operators to make necessary decisions in critical situations. Unlike traditionally used metal forming processes, these machines have improved production, lowered costs and create large quantities of identical metal components at the same time.

“The widespread adoption of the bending process across various industries to improve the stability, durability and quality of the products represents the major factor driving growth of the global metal stamping industry. Metal stamping is widely utilised in the aerospace industry to manufacture frames and channels that are used in ultra-lightweight aircraft. In consumer electronics, metal stamping is used to produce metal frames used in mobile phones, headphones, speakers, gamepads and controllers. Apart from this, with the growing demand for electric and hybrid vehicles, there has been a significant rise in the adoption of hot stamping technology,” added the analyst.

Metal stamping is widely implemented in the automobile industry to convert sheet metal into exterior and interior parts, such as auto-body panels and various appliance parts. Increasing investments in major automotive hubs (such as China, Japan and India) in new production facilities are also expected to escalate the demand for motor-stamped parts in the coming years.

“The development of new materials, such as advanced high-strength steels (AHSS), has increased demand for metal stamping, which produces higher contact pressure at the die-blank interface than conventional materials. Leading metal stamping companies are developing technologically advanced stamping methods, such as computer-aided design (CAD) processes and digital measuring systems that significantly reduce processing time. The introduction of 3D printing technology and additive fabrication, as well as extensive research and development (R&D) activities, are also contributing to market growth,” continued the analyst.

For more information about this report, see https://www.researchandmarkets.com/r/d66jcg

Recent comments