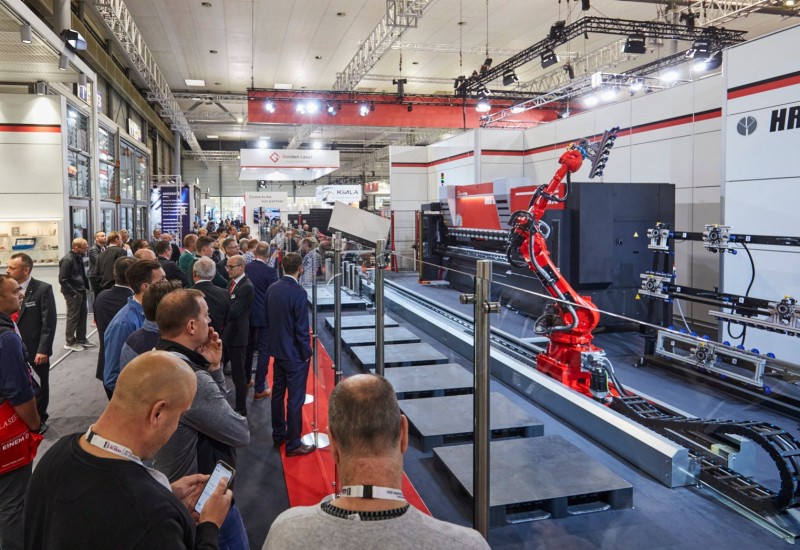

Robotics in review

Today, industrial robots are an essential part of many manufacturing processes across a broad range of market sectors. Robots, as part of a modern manufacturing strategy, bring a host of benefits including process consistency; improvements in productivity quality and yield; high levels of flexibility and the ability to free humans from dirty, tiring or hazardous working environments. Whether it is part-handling; assembly; machine-tending; welding; cutting etc., robots are playing an increasingly important role in our manufacturing facilities.

“Integrating robots into a manufacturing process can deliver significant improvements in productivity. Once the robot programme has been fine-tuned, the cycle time for every operation will be the same. This predictable performance, combined with the ability to operate around the clock at high levels of reliability, makes it possible to consistently achieve and maintain productivity levels. Robots also bring benefits in applications that require high levels of cleanliness such as those found within the medical, pharmaceutical and food sectors,” explained BARA, the British Automation and Robot Association.

“The dynamic and highly competitive nature of today’s marketplace, combined with changing regulatory requirements in medical, healthcare and food plus the trend towards vehicle personalisation within the automotive sector, means that automation will continue to play an increasingly important role in a variety of manufacturing sectors,” it continued.

Why automate?

“The common reasons cited by companies for believing that automation is not appropriate for them include: it’s too expensive, volumes are too low, product mix is too high or the process needs human intervention for dexterity or inspection purposes. It is true that automation requires both justification and a return on investment, and at lower volumes this will be a more difficult calculation. However, by taking into account other factors such as ergonomic benefits; improved health and safety; quality and yield improvements; reduced skill levels and the ability to implement changeovers more quickly, the case for automating may become much stronger,” explained BARA.

Taking a longer-term view on the investment required to automate, especially if the system includes robots, can make a significant difference. After all, the robots will remain at peak performance for many years and just having taken the step to automate can often strengthen the customer-supplier relationship.

For high product mixes, automation is not only able to deal with multiple product variants but brings with it greater levels of process and quality control.

To read the rest of this article, see https://joom.ag/3u6I/p16

Recent comments