Punch, cut and bend

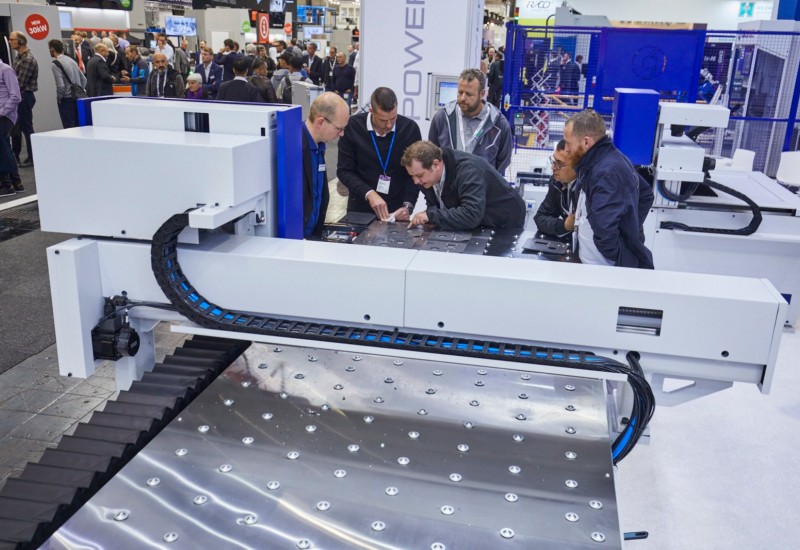

Image caption: Pivatic’s CEO, Jan Tapanainen, outlines the company’s latest projects, strategic initiatives and new investments to ISMR at Blechexpo/Schweisstec.

Pivatic Oy designs, manufactures and markets punching, cutting and bending machines, as well as lines, for the sheet metal manufacturing industry. Its solutions are tailored to customer requirements and designed for productivity and sustainability. A member of The Ursviken Group, its production facilities and headquarters are at Hyvinkää, Finland. It also has a wide global sales and partner network of more than 30 representatives.

Pivatic’s punching roots go back to 1975 when it was established as Toolsystem Ky producing quick-change tooling systems for sheet metal presses. In 2015, it celebrated its 40th anniversary with over 450 production lines delivered globally and a strong sales and partner network established in over 27 countries. Today, it offers complete automated solutions with a wider selection of technologies and can integrate storage systems (Remmert), panel benders (RAS) or rollforming equipment (Samesor) and coil-fed lasers (Eagle) into its lines to increase flexibility for small batch or kit production.

ISMR met Pivatic’s CEO, Jan Tapanainen, at this November’s Blechexpo/Schweisstec exhibition in Stuttgart. He outlined some of the company’s latest new projects, strategic initiatives and investments to ISMR, along with his thoughts on global markets, trends, challenges and opportunities.

ISMR: Which investments have you made over the past two-three years (machine tools, factory, staff etc.)?

JT: We have been investing in more staff, especially in our software engineering department. We are now ready to expand our factory in Hyvinkää, Finland, and double the assembly hall area. Our current production and office space is 4600 square metres. We have also been continuously increasing our R&D activities and aim to have some new developments ready to launch at the EuroBLECH exhibition in Hanover next year.

We also continue to develop partnerships with other manufacturers on our production lines. For example, we have been working with Polish laser manufacturer, Eagle, on a new coil laser cutting line for a customer in Finland and Sweden. This large project incorporates a new rapid 2D laser built especially for coil processing as well as automatic and reliable sorting. Material utilisation is much better, with very little scrap and waste. We are planning to bring it to the EuroBLECH exhibition in Hanover next year.

Our other R&D projects are focused on software and dynamic nesting; coil straightening and a fully servo electric bending machine. These are important projects for the future. We always try to find out what customers need when we start discussions or invest in R&D. We have an engineering mindset aimed at finding customised solutions to challenges; very seldom do we say ‘no’.

ISMR: What are your views on the current global business climate/markets for sheet metal professionals? How do you view 2024?

JT: Three years ago, when COVID-19 started, the sheet metal industry had a tough time. Mid-sized companies like ours were unable to travel and meet customers. Luckily, our existing customers placed repeating orders with us. The sheet metal industry then faced spiralling material and component cost increases last year, and long delivery times for some customers due to supply chain disruptions (especially for parts containing electronics and semi-conductors). This year and last year, interest rates have shot up which have negatively affected capital investments.

This year, consumption in Europe has been slowly stabilising. Some of our customers, who were running high volumes, were not investing up until the Summer and were delaying, cancelling or postponing projects. Despite this, we kept on bringing out new line innovations and better value solutions.

I am pleased to report that, over the last two months, the situation has changed and a lot of ‘on-hold’ projects have now been reactivated with decisions expected at the end of the year. This is partly because our long lead times (10-14 months) mean that customers need to make decisions now for operations in 2025 which industry generally thinks to be much better. This puts us on a different cycle than most companies and stand-alone machine builders here at the exhibition.

Our order backlog is strong for next year. If things go as I expect by the end of the year, then 2024 should be a better year for us.

ISMR: Please outline your strategic and technical focus for the company.

JT: Our main customer areas are in North America and Europe. We have installed several lines in China, South Korea and India. We have a sister company in the United States (our main market) and a branch office in Germany (DACH is our second biggest market) and Scandinavia.

To read the rest of this article in the November 2023 issue of ISMR, please see https://joom.ag/ztnd/p24

Recent comments