Staying ahead

In the September 2023 issue of ISMR, we highlight a selection of global trends, challenges and opportunities to help manufacturers stay ahead in 2023.

======

Issues such as high energy prices; wage inflation; supply chain and cost pressures as well as cybersecurity will remain critical challenges in 2023.

“Despite supply headwinds, labour shortages and an uncertain economic environment, the manufacturing industry continues to surpass the expectations of previous years. To maintain this growth, leaders should leverage digital technologies, adopt strategies for the future of work and drive supply chain resiliency,” commented Deloitte.

We therefore highlight a selection of global trends, challenges and opportunities to help manufacturers stay ahead in 2023.

Skills and labour shortages

The manufacturing industry has long struggled to attract, hire and retain young talent and suffered from labour shortages as well as skills and diversity gaps. Many of its employees are aged 55 or over. The Great Resignation saw thousands of employees voluntarily leave their jobs in search of opportunities with better wages, better working environments and better work-life balance.

The challenge has been intensified by digitalisation and the COVID-19 pandemic and then, more recently, by issues such as low unemployment and wage inflation. Creating an inclusive work environment that promotes fairness and equality in turn helps to engage employees. The trickle-down effects of employee engagement are well known including improved business results, customer satisfaction and productivity.

“Some firms have increased pay or begun to offer other financial awards such as retention bonuses or, more recently, one-off financial help to cope with the increased cost of living. Others are investing more in workforce training and development, so that employees have opportunities to progress and develop within the firm and take their career further. Non-financial benefits, such as offering flexible working (where possible) can also help,” explained industry organisation, Make UK.

Digital technologies

“Manufacturers are investing in a multitude of new technologies including artificial intelligence, virtual reality, machine learning and more. Automation and robotics are enhancing workers’ abilities but will also require many more high-skilled employees. Although the workforce shortage is a challenge, digital technologies will help manufacturers become more resilient, efficient and profitable,” commented the National Association of Manufacturing (NAM) in the United States.

Augmented Reality (AR), Virtual Reality (VR) and Artificial Intelligence (AI) are just some of the technologies that manufacturers are adopting to enhance, streamline and add efficiencies to their operations. The smart use of digitalisation, including artificial intelligence, in combination with robotics and automation solutions can bring about major leaps in productivity and help to raise competitiveness on a long-term basis.

“Manufacturers should be embedding artificial intelligence, blockchain and robotics in their operations today. The convergence of these new technologies will fundamentally shift the manufacturing enterprise. A new workforce with the ability to augment these technologies is beginning to emerge,” added analyst E&Y.

“The models that drive business transformation will be those that can best leverage the huge potential of digital technology to meet evolving customer demands, whilst avoiding the associated investment risks and data privacy pitfalls,” added Dassault Systemes.

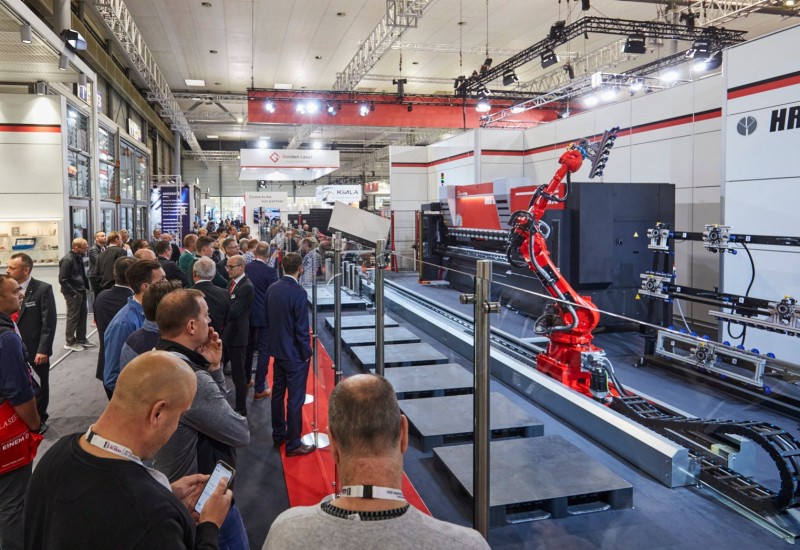

Robotics and automation

The stock of operational robots around the globe hit a new record of about 3.5 million units, with the value of installations reached an estimated US$ 15.7 billion according to the International Federation of Robotics (IFR). It has analysed the top five trends shaping robotics and automation in 2023: energy efficiency; reshoring; ease of use; Artificial Intelligence (AI) and digital automation; and a second life for industrial robots.

Today’s robots are designed to consume less energy, which leads to lower operating costs. Robot programming has also become easier and more accessible to non-experts. Connected robots are also transforming manufacturing. The improvement of connectivity and safety technologies means that we are increasingly seeing more powerful autonomous mobile robots (AMRs) on factory floors. Cobots (working in collaboration with human operators) are also becoming more prevalent.

Manufacturers are also employing more automation in and around their machine tools and production to offset labour shortages and improve their productivity.

Supply chain resilience

“As manufacturers face long lead times, increased costs and a scarcity of raw materials, they are taking steps to boost supply chain resilience through reshoring, cybersecurity, increased supplier pools and more,” commented the National Association of Manufacturing in the United States.

The COVID-19 pandemic raised awareness around the manufacturing industry’s dependence on offshoring facilities when critical supply shortages led to production issues. Global supply chain disruption has made it challenging for manufacturers that source materials from other countries, which has also sparked renewed interest in nearsourcing.

However, supply chain resilience is also not just about reacting to present problems. The speed of market and technological transformation means that for businesses to remain resilient, they need to keep an eye on where their sectors are going and what that means for their supply chains in the future.

To read the rest of this article in the September issue of ISMR, see https://joom.ag/asNd/p24

Recent comments